The Minting Process: How Coins Are Created

From Blank Metal to Gleaming Treasure

Ever wondered how a plain sheet of metal transforms into that shiny coin jingling in your pocket? It’s a process as intricate as crafting a piece of fine jewelry. It all begins with planchets—small, blank discs of metal that hold the promise of becoming currency. These aren’t just any scraps of metal; they’re meticulously cut from sheets of alloys like copper and nickel to ensure consistency in size and weight.

Then comes the magic moment: striking. Picture it—a high-powered press slamming down with immense force, imprinting every detail onto the blank surface. This isn’t a casual press; it’s precision engineering at work, producing up to 750 coins per minute! Those designs you admire, from the stately Lincoln Memorial to the bold eagle, are brought to life in an instant.

- Heating: To ensure the metal stays flexible and doesn’t crack, some coins go through annealing—a fancy term for heating and cooling.

- Polishing: Before striking, planchets are polished to perfection, ensuring a flawless shine.

Every sound of those presses echoes history in the making. It’s industrial poetry, with each coin telling its own story.

Quality Control and Designing the Perfect Coin

Where Precision Meets Imagination

Crafting a coin isn’t just about metal and machinery—it’s about weaving history, art, and purpose into a perfect little circle. Every detail, from the ridges on the edge to the tiniest engraving, has a story. Imagine holding a freshly minted coin. That satisfying weight in your hand? It’s the result of meticulous design and intense quality control measures.

Engineers and artists work like two sides of the same coin (pun intended!), merging creativity with technical expertise. Every design must be iconic yet functional—beautiful, but durable enough to endure years of jingling against keys and sitting in pockets. From the proud eagle on the quarter to the symbolic torch on the dime, each image evokes emotion while standing out to the naked eye.

The Triple Check for Flawless Perfection

Before coins are cleared for circulation, they undergo laser-focused scrutiny. Why? Because no imperfection, however tiny, gets a free pass. The process includes:

- Visual inspections by trained human eyes and high-speed cameras.

- Weight testing to ensure each coin fits within ultra-precise tolerances.

- Hardness checks to confirm durability under everyday pressure.

Each coin must meet its golden standard—or, well, silver, copper, or nickel standard! Quality isn’t just checked; it’s obsessed over.

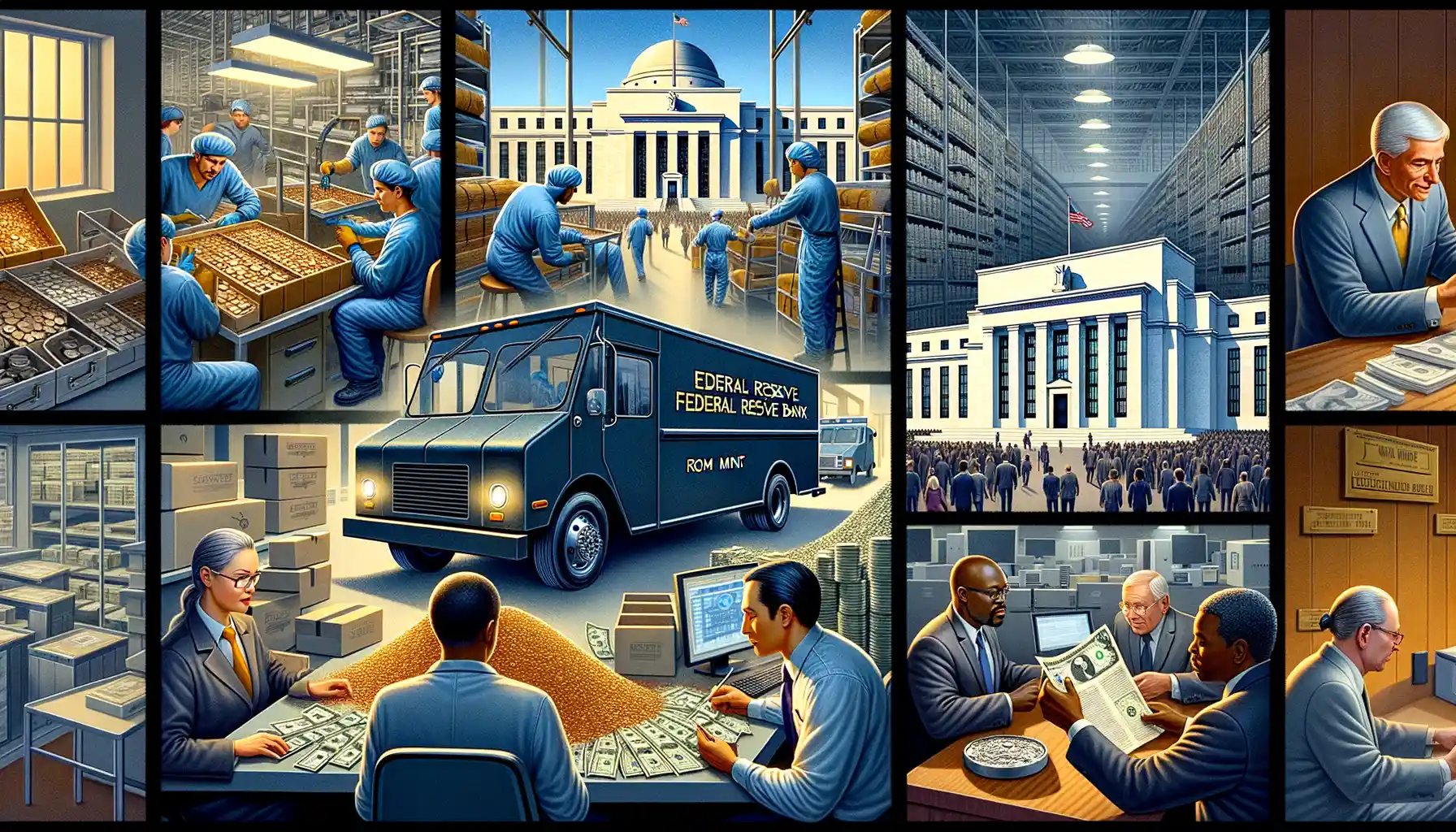

Distribution: From Mint to Federal Reserve Banks

Where Coins Begin Their Adventure

Picture this: freshly minted coins gleaming like tiny treasures, ready to set off on their incredible journey. But before they land in your pocket, these metallic marvels take a fascinating detour. Straight out of the U.S. Mint, coins are meticulously counted, sorted, and packed with precision that would make even the most detail-oriented person envious.

Each batch is carefully bundled into heavy-duty bags or rolls, depending on the denomination, and then those bundles embark on their first road trip—to the vaults of the Federal Reserve Banks. These institutions act as the great distributors of currency, ensuring every corner of the country gets its fair share of circulating cash.

- Coins leave the Mint secured in armored vehicles, guarded like priceless artifacts.

- They arrive at Federal Reserve Banks, which serve as distribution hubs for commercial banks.

The Pulse of Distribution: Federal Reserves at Work

Imagine a Federal Reserve Bank as the beating heart of a vast, financial circulatory system. Here, coins are stored, sorted, and allocated to meet regional demand. When your local bank or supermarket runs low on pennies, dimes, or quarters, they place an order with their nearest Federal Reserve Bank. And voilà—those coins you casually toss into your piggy bank are soon replenished from this enormous stockpile.

From the moment they leave the Mint, these coins are destined to weave themselves into countless daily interactions, carrying stories, energy, and value with every exchange.

Circulation: How Coins Reach the Public

From Banks to Wallets: A Coin’s Big Adventure

Ever wondered how a shiny new coin ends up jingling in your pocket? It’s not magic—it’s a journey full of twists and turns. Once coins leave the Federal Reserve Banks, their real adventure begins. Think of it like a relay race, with banks, businesses, and you as part of the handoff.

Here’s where the action happens:

- Commercial banks order coins from the Federal Reserve to meet public demand. They’re like the middlemen in this story.

- Coins then move into cash registers at your local grocery store, vending machines, or even parking meters. Suddenly, they’re everywhere.

And then, well—you. That quarter could go from paying for a morning coffee to being dropped into a kid’s piggy bank by day’s end. The flow is constant, seamless, and surprisingly personal.

The Human Touch Behind Every Circulation

Every time you hand over a coin, you’re part of this never-ending cycle. Maybe that penny helped someone make exact change for a meal today. Or maybe you saved it, thinking about its tiny contribution to your next goal. Coins don’t just circulate—they build stories, connect strangers, and serve needs far beyond the clinking sound in your wallet.

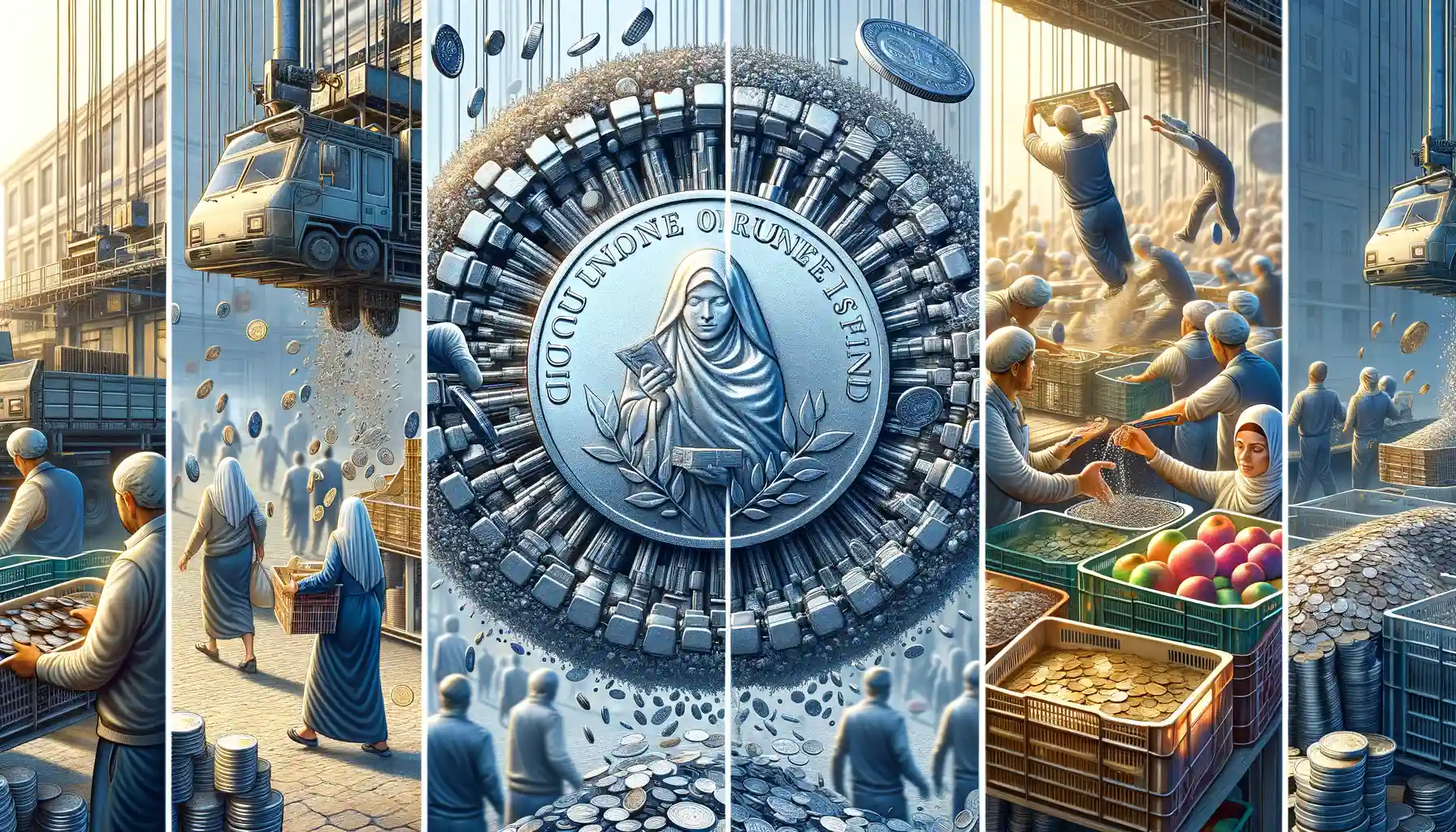

Recycling and Retiring Old Coins

Where Coins Go When Their Time Is Up

Have you ever wondered what happens to a coin when it’s too worn or damaged to keep doing its everyday job? Like an old friend with a good story, even coins eventually retire. But don’t worry—they’re not just tossed aside! The process of recycling coins is like letting them be reborn into something entirely new.

When coins show signs of heavy wear—like deep scratches, faded designs, or even strange bends—they get pulled aside. These trusty workhorses are sent to facilities where the magic happens. Here’s how they leave their past lives behind:

- Collected and Inspected: Banks or businesses set aside heavily circulated coins and hand them over to the U.S. Mint for review.

- The Meltdown: Metals are melted down and transformed into gleaming fresh material ready for new coins—or maybe even another product entirely!

Fun Fact: A single nickel might be reincarnated as part of a shiny dime or even a piece of industrial equipment. It’s a reminder that even in retirement, coins play a role in the bigger economic picture.